Carefully observed decisions and firing instructions for creating with glass. Thoughts on color, placement and reactions achieved through the glass work.

Monday, February 10, 2014

BEST Basic Fuse Firing for my kiln

Layering stacks of scrap glass to get fused pieces to cut as multi color leaves or decorations for other pieces. I fused this with Bullseye Basic Fuse Firing schedule with slight alteration. Instead of 1490 degree processing temperature, i went to 1475 degrees instead. All else stayed the same.

400 dph........................................1225 degrees..................................hold 30 min

600 dph........................................1475 degrees..................................hold 10 min

FULL..............................................900 degrees..................................hold 1 hour

100 dph..........................................700 degrees...................................hold 0 min

FULL..............................................70 degrees.....................................OFF

Sunday, February 2, 2014

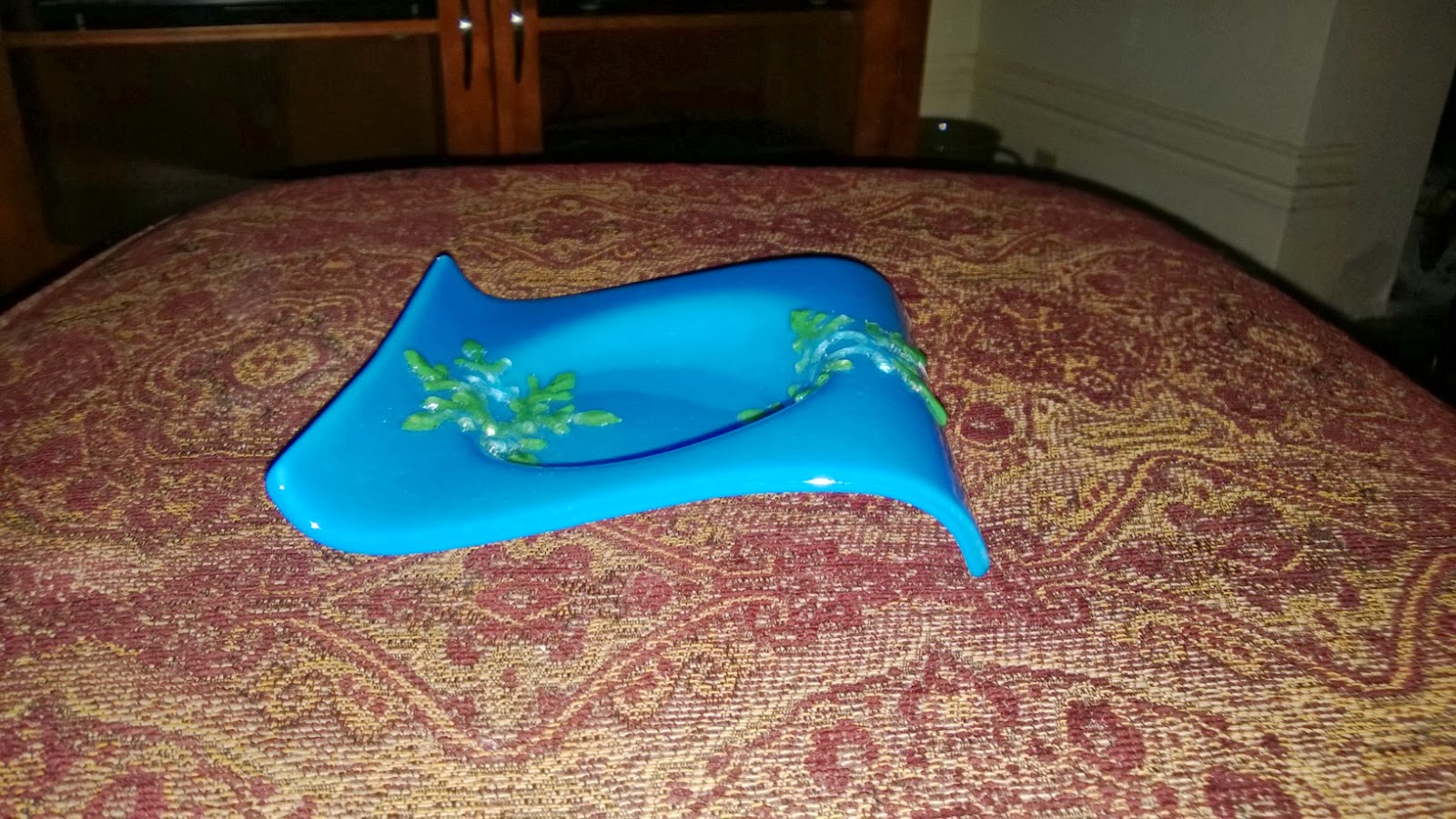

Snowflake wave dish with recess for candle, or candy or keys, whatever

I am doing another wave mold with recess. Already did a white and green one, which was very pretty, and had a few errors but nothing too bad. I forgot to take a picture of it, It is now at my gym, hoping that someone will buy it. And I am doing another, this one has a 3mm blue base, very pretty color, topped with a 2mm clear glass that was cut 1/8th of an inch bigger than the base, with the aim that the top would overlap and include the bottom, making a more finished piece. I ground the pointy corners first. After it comes out of the kiln, I will tack fuse some snowflakes on it and then slump it into the mold. For the panel, I used the following firing schedule:

300dph.............................................1250degrees.....................................hold 30 min

600dph..............................................1420degrees....................................hold 10 min

Full....................................................900degrees......................................hold 1 hour

100dph...............................................300 degrees.....................................OFF

I am fusing only 5mm piece so the corners should somewhat round even though the temperature is not that high. This time I will remember a picture.

Well that came out well, except that it pulled all the kiln wash off of the shelf and I had to soad it in vinegar and water and then scrub it to remove the residue. I placed a sheet of thin fire paper down and put the panel on which I placed to snowflakes. I also added two small projects that I did, wishing to tack fuse those with the following schedule.

300dph.......................................1225 degrees...............................hold 30 min

400dph.......................................1350 degrees...............................hold 10 min

Full...............................................900 degrees...............................hold 1 hour

100dph.........................................600 degrees...............................OFF

This is a higher temperature than the last tack fusing of snowflakes. I wanted less definition.

The above piece was slumped at the following temperature and I think that this schedule is the BEST for this mold:

300dph.......................1220degrees................................hold 40 min

FULL............................900degrees................................hold 1 hour

100dph..........................600degrees...............................OFF

300dph.............................................1250degrees.....................................hold 30 min

600dph..............................................1420degrees....................................hold 10 min

Full....................................................900degrees......................................hold 1 hour

100dph...............................................300 degrees.....................................OFF

I am fusing only 5mm piece so the corners should somewhat round even though the temperature is not that high. This time I will remember a picture.

Well that came out well, except that it pulled all the kiln wash off of the shelf and I had to soad it in vinegar and water and then scrub it to remove the residue. I placed a sheet of thin fire paper down and put the panel on which I placed to snowflakes. I also added two small projects that I did, wishing to tack fuse those with the following schedule.

300dph.......................................1225 degrees...............................hold 30 min

400dph.......................................1350 degrees...............................hold 10 min

Full...............................................900 degrees...............................hold 1 hour

100dph.........................................600 degrees...............................OFF

This is a higher temperature than the last tack fusing of snowflakes. I wanted less definition.

The above piece was slumped at the following temperature and I think that this schedule is the BEST for this mold:

300dph.......................1220degrees................................hold 40 min

FULL............................900degrees................................hold 1 hour

100dph..........................600degrees...............................OFF

Subscribe to:

Posts (Atom)