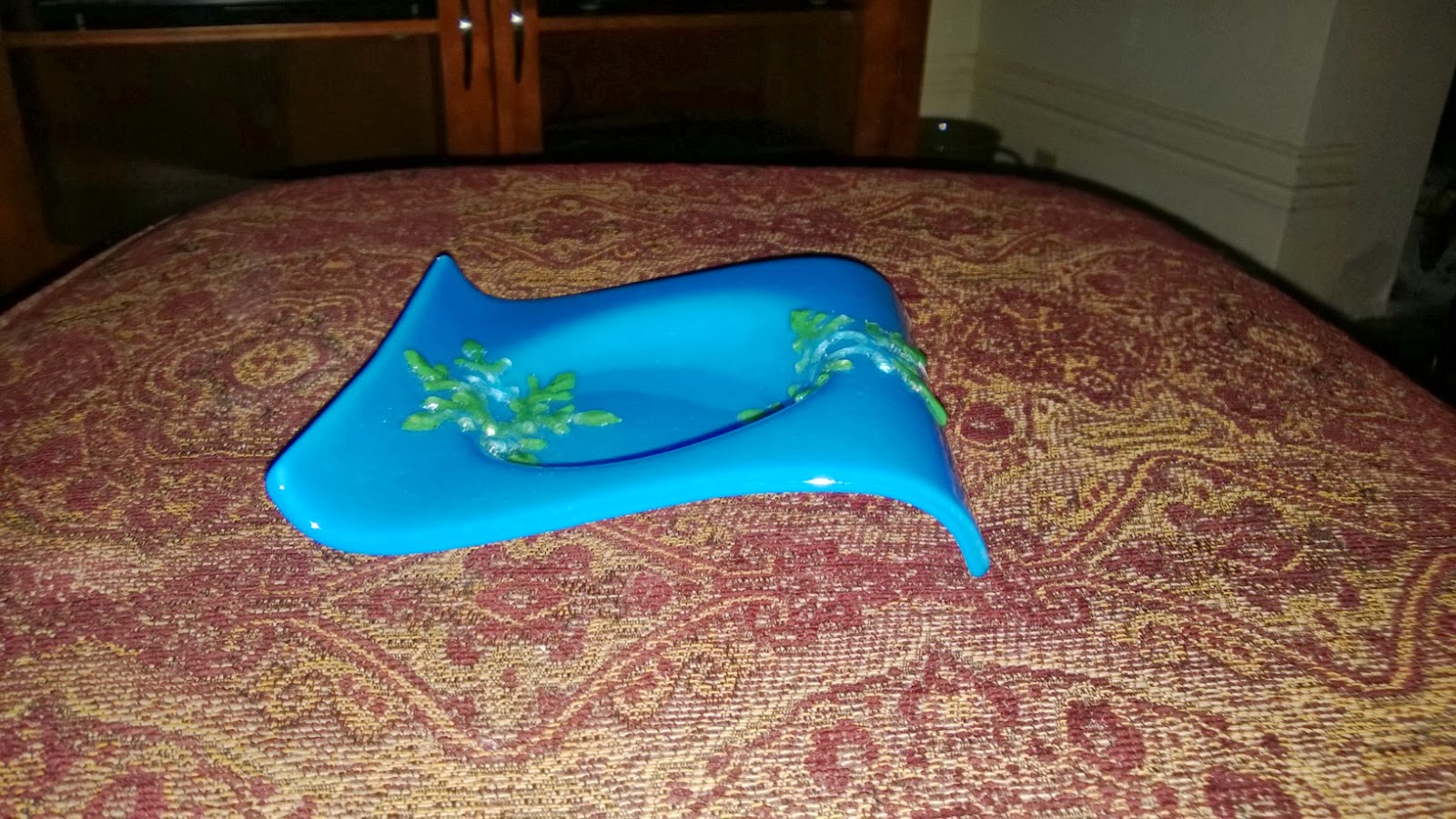

I am doing another wave mold with recess. Already did a white and green one, which was very pretty, and had a few errors but nothing too bad. I forgot to take a picture of it, It is now at my gym, hoping that someone will buy it. And I am doing another, this one has a 3mm blue base, very pretty color, topped with a 2mm clear glass that was cut 1/8th of an inch bigger than the base, with the aim that the top would overlap and include the bottom, making a more finished piece. I ground the pointy corners first. After it comes out of the kiln, I will tack fuse some snowflakes on it and then slump it into the mold. For the panel, I used the following firing schedule:

300dph.............................................1250degrees.....................................hold 30 min

600dph..............................................1420degrees....................................hold 10 min

Full....................................................900degrees......................................hold 1 hour

100dph...............................................300 degrees.....................................OFF

I am fusing only 5mm piece so the corners should somewhat round even though the temperature is not that high. This time I will remember a picture.

Well that came out well, except that it pulled all the kiln wash off of the shelf and I had to soad it in vinegar and water and then scrub it to remove the residue. I placed a sheet of thin fire paper down and put the panel on which I placed to snowflakes. I also added two small projects that I did, wishing to tack fuse those with the following schedule.

300dph.......................................1225 degrees...............................hold 30 min

400dph.......................................1350 degrees...............................hold 10 min

Full...............................................900 degrees...............................hold 1 hour

100dph.........................................600 degrees...............................OFF

This is a higher temperature than the last tack fusing of snowflakes. I wanted less definition.

The above piece was slumped at the following temperature and I think that this schedule is the BEST for this mold:

300dph.......................1220degrees................................hold 40 min

FULL............................900degrees................................hold 1 hour

100dph..........................600degrees...............................OFF

No comments:

Post a Comment