But now a mold from Creative Paradise Inc.

This is smaller, 8 3/4" by 8 3/4" and the design is not as pretty as the Colour de Verre molds but it might look nice. I am fusing a red streaky piece of glass which has autumn colors in it as well on this mold along with a clear base. I picked the red with the idea of having it look like a veined red maple leaf and I used the following firing schedule:

300dph.....1360 degrees....................hold 20 min

300dph.....1465 degrees...................hold 5 min

Full.............900 degrees...................hold 1 hour

100dph........700 degrees..................Off

So this is how it came out, pretty soft red glass with veined leaf pattern. I am currently slumping it into the mold which is 4 5/8th square. Unfortunately I wound up cutting one side 5 inches long, so the glass itself is a little big for the slumping mold. I hope this does not cause a problem. I slumped a piece of glass that was a little bigger than its mold before and nothing too bad happened. We shall see.

Well, out of the kiln it came and it slumped into the shape fine but the bottom of the piece was covered with what might have been devitrification. I tried to polish it off with my diamond hand pads but was left with a few scratches on the bottom, which perhaps will come off with more finer polishing with the hand pads. Mark suggest a felt bottom and I will check that out at Louis Does or in a sewing store when i go for pins

Before moving on to some other things, full fusing flower parts and doing a screen melt, I am going to post pictures of the other texture molds that I have. They are cool.

Before moving on to some other things, full fusing flower parts and doing a screen melt, I am going to post pictures of the other texture molds that I have. They are cool.This was done with the botanical mold. and it came out fine, a really pretty pattern. We see it now with white remnants of mold spray. That comes off. The other problem is that I stupidly added a clear piece which was much bigger than the brown piece of glass and that will have to be ground down before slumping it. I also used the following schedule off of the Colour de Verre website.

100dph.........................................300 degrees....................hold 30 min

150dph.........................................1250 degrees.................hold 30 min

150 dph........................................1370 degrees............................hold 5 mins. And here is where they gave me a range for the process temperature. The range was from 1350 to 1400 degrees and I choose 1370 degrees.

Full.............................................900 degrees............................hold 1 hour

100 dph.......................................700 degrees............................Off

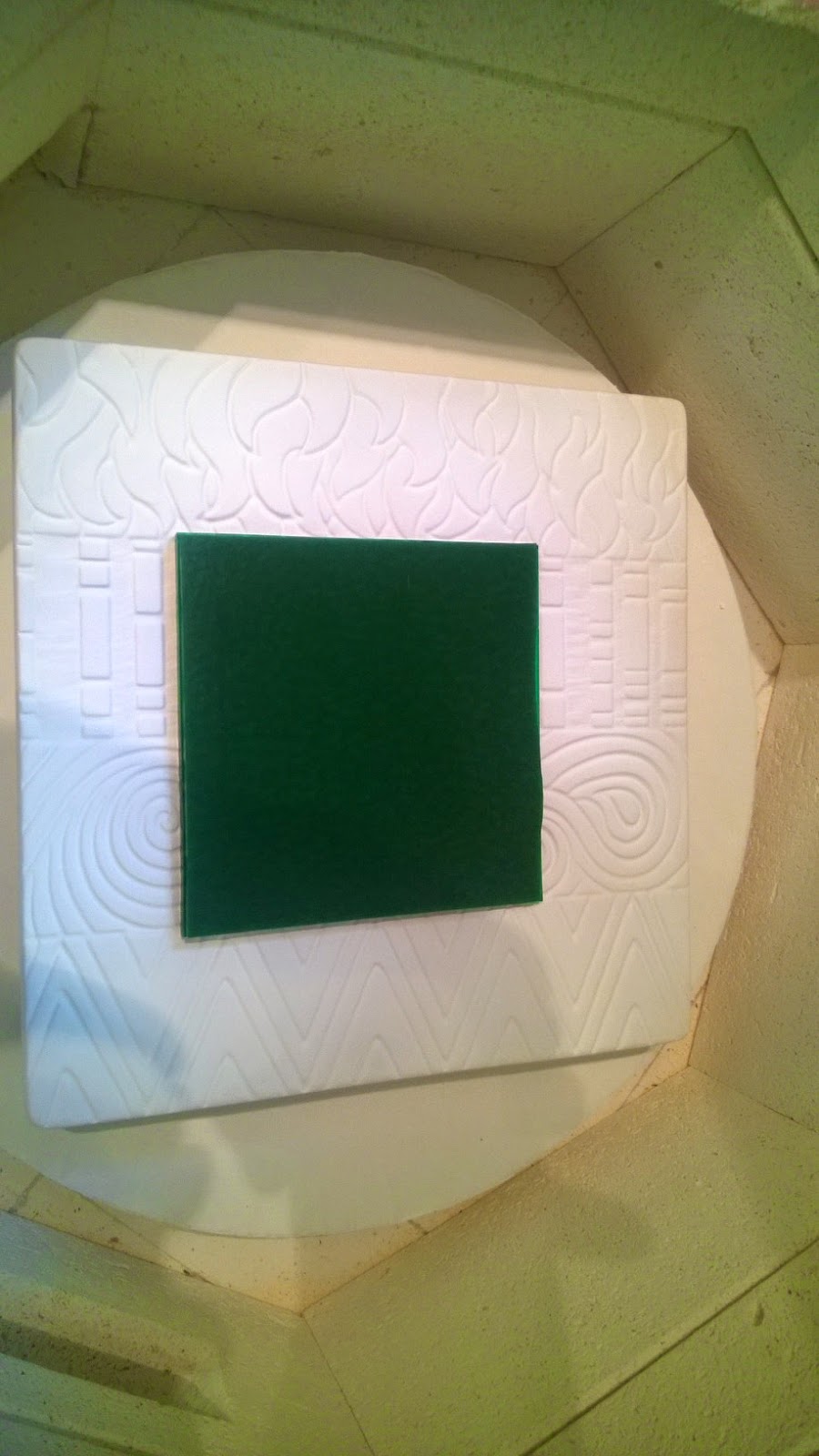

Once getting this clean I noticed a few spots that would not come off. Probably some sort of devitrification, so the next firing will be an experiment. I am using two piece of 3mm clear glass and I placed it on the spiral pattern fusing mold. Deep spirals many different sizes, very pretty pattern. I cleaned the glass carefully and I am also going to change the firing schedule. I am lowering the processing temperature to 1355 degrees and holding that for 3 minutes. Going to clean off my work table and make an extra effort to keep that area clean, putting paper down first and then the grate on which I cut the glass next. I think that my kiln fires hot so perhaps this will help. Also I put the mold on a 2 inch stand or kiln furniture even though they suggested 1 inch. This will bring it closer to the heat but those pieces or stand were already in there and I left them in. so this experiment will not be as valid as I could get. My laziness is a problem. But lets just see.

So as you can see it came out pretty well except for lots if what appears to be bubbles or flecks of glass, but it does not look bad it kind of looks good. I do not know exactly what this means because I read yesterday that devit is often in dark opaque glass and in this experiment I used clear. I guess the best experiment will be on dark opaque with the temperature I used in this firing. I slumped it and it came out ok.

The next experiment will be with a dark opaque glass with clear on the bottom and using the firing schedule that I used for the above. In between this I tried to fire polish a screen melt and it did not quite work. That was the second time I tried a fire polish schedule for that piece and the first time the kiln did not complete the full schedule and it stopped with error message PF2. But my next project will be another attempt at the botanical pattern melt and if that works then I will assume that there may be some problem with the glass.

Well, it came out a little better but it still had parts which look like as Mark describes them "dusty". I had fewer of these spots than the previous ones. Perhaps I can only use clear or transparent glass on these deeper molds. For the next experiment after I slump this blue piece will be too use a smaller less deep mold.

300 dph.............................1360 degrees........................hold 20 mins

300 dph..............................1465 degrees.......................hold 10 mins

Full.......................................900 degrees......................hold 1 hour

100 dph.................................700 degrees.....................off

Again, because I am not covering the whole mold, only using a portion of it I will lower the processing temperature to 1455 degrees and hold for 5 mins. Again, since this mold is not as deep or heavy and It is not held for such a long time or goes up to its processing temperature as quickly, I will try it with an opaque glass but see if I can find a light colored opaque on the bottom of which I will put clear.