This worked nicely for a 6mm 2 layers of clear glass with premade fused flowers on top along with stringers and chunky mixed color frit along with fine grit. The schedule I used is as follows:

300 dph...............................................1150 degrees................................hold 20 mins

Full......................................................1425 degrees................................hold 12 mins

Full........................................................900 degrees................................hold 1 hour

150 dph.................................................800 degrees.................................hold 2 mins

Off

Three of the four corners fused fully. One of the corns appears uneven, like the top layer was a little short of the bottom and it did not quite meet it. But not bad all in all. I had originally intended to slump it but now I think it would be better to keep it as a tile.

Contour is between tack fusing and full fusing, a nice mixture not a precisely defined, bumpy surface but not flat and loosing all its surface texture.

Carefully observed decisions and firing instructions for creating with glass. Thoughts on color, placement and reactions achieved through the glass work.

Friday, May 2, 2014

Wednesday, April 30, 2014

slumping small 3 and 3/4 inch dish

300dph.......................................................1215 degrees..........................hold 15 mins

Full.............................................................900 degrees............................hold 1 hour

100 dph......................................................700 degrees.............................hold 1 min

off

Notice slight pulling on the left side. There is a little unevenness around the edges. In the next slump I have decreased the processing temp to 1210 degrees and I will hold at the processing temp for 30 mins instead of 15mins. Lets see how this effects things. Well this one split in half, what happened here I do not know. I am going to watch Bullseye video on slumping again.

Friday, April 4, 2014

My new computer and glass fusion

Two new pieces in the kiln, about 3 and 3/4 inch square, each with one layer of 2mm clear glass, one with one layer of 3mm clear glass covered with a few pieces of decorative glass and the other covered with one layer of 2mm white glass and a perfused art glass made a while ago by me. I looked up fusing schedules for small pieces and I put together this one. It is different from the fusing schedule I used with the snowflake pieces, but for those I fused together only two layers of glass equaling 5mm of glass. So this firing schedule goes as follows:

400dph.........................................1150 degrees......................................hold 20 mins

full................................................1470 degrees......................................hold 12 mins.

full.................................................900 degrees........................................hold 20 mins

150 dph..........................................800 degrees.......................................hold 2 mins.

Off

The schedule I used for the two small snowflake items was as follows. That one worked well. Lets see how this one works.

400dph.......................................1250 degrees....................................Hold 30 min.

600dph.......................................1420 degrees....................................Hold 10 min.

FULL............................................900 degrees......................................Hold 60 min.

100 dph........................................300 degrees....................................off

I took one of the two pieces. The whole idea is to determine whether one layer of glass with stuff on top in this 3 and 3/4 inch square format looks better than 2 layers of glass with stuff on top, or whether it looks equally good. For this project I want to work on slumping. I like the look of stringers on top of clear glass, alongside two thicker strips of glass and then slumped. The problem was that I used only layer of of 3mm clear glass and the edges pulled a little where I had placed the bigger strips of red glass. Actually they only pulled after slumping. So to solve this I have to lower the slump temperature or hold a little longer. Thats how I solved it before with the snowflake square, or put another piece of glass underneath it. So when I take this current piece of glass out of the kiln I will see how it work with 2 layers of glass and stuff on top.

400dph.........................................1150 degrees......................................hold 20 mins

full................................................1470 degrees......................................hold 12 mins.

full.................................................900 degrees........................................hold 20 mins

150 dph..........................................800 degrees.......................................hold 2 mins.

Off

The schedule I used for the two small snowflake items was as follows. That one worked well. Lets see how this one works.

400dph.......................................1250 degrees....................................Hold 30 min.

600dph.......................................1420 degrees....................................Hold 10 min.

FULL............................................900 degrees......................................Hold 60 min.

100 dph........................................300 degrees....................................off

I took one of the two pieces. The whole idea is to determine whether one layer of glass with stuff on top in this 3 and 3/4 inch square format looks better than 2 layers of glass with stuff on top, or whether it looks equally good. For this project I want to work on slumping. I like the look of stringers on top of clear glass, alongside two thicker strips of glass and then slumped. The problem was that I used only layer of of 3mm clear glass and the edges pulled a little where I had placed the bigger strips of red glass. Actually they only pulled after slumping. So to solve this I have to lower the slump temperature or hold a little longer. Thats how I solved it before with the snowflake square, or put another piece of glass underneath it. So when I take this current piece of glass out of the kiln I will see how it work with 2 layers of glass and stuff on top.

Tuesday, April 1, 2014

Okay , trying slumping again. This is a small mold 3 and 3/4 inches square. I lay a square of one layer of 3mm clear glass govered with stringers and two slender pieces of red glass on the top of the mold and will use the following schedule:

300degrees,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,1180 degrees,,,,,,,,,,,,,,,,,,,,,,,,,,,,,hold 10 mins

Full......................................900 degrees....................hold 1 hour

100dph.................................700degrees....................hold 1 minute

Full.........................................70 degrees....................OFF

It is a small piece of glass. Should not take too much to do what it has to do.

Monday, March 17, 2014

Mosaics as a digression and another tack fuse

I just completed a 4 week class on mosaics in Waterville and thought it was really good. Almost completed my second project, both need grouting and I dont have all the relevant equipment yet. It is like doing a puzzle, and you have to keep color in mind as well as shape and the direction of the pieces, lots of new things to think about. In the future I can do projects with old china dishes, or clue my fused pieces on surfaces, its not too hard.

Monday, February 10, 2014

BEST Basic Fuse Firing for my kiln

Layering stacks of scrap glass to get fused pieces to cut as multi color leaves or decorations for other pieces. I fused this with Bullseye Basic Fuse Firing schedule with slight alteration. Instead of 1490 degree processing temperature, i went to 1475 degrees instead. All else stayed the same.

400 dph........................................1225 degrees..................................hold 30 min

600 dph........................................1475 degrees..................................hold 10 min

FULL..............................................900 degrees..................................hold 1 hour

100 dph..........................................700 degrees...................................hold 0 min

FULL..............................................70 degrees.....................................OFF

Sunday, February 2, 2014

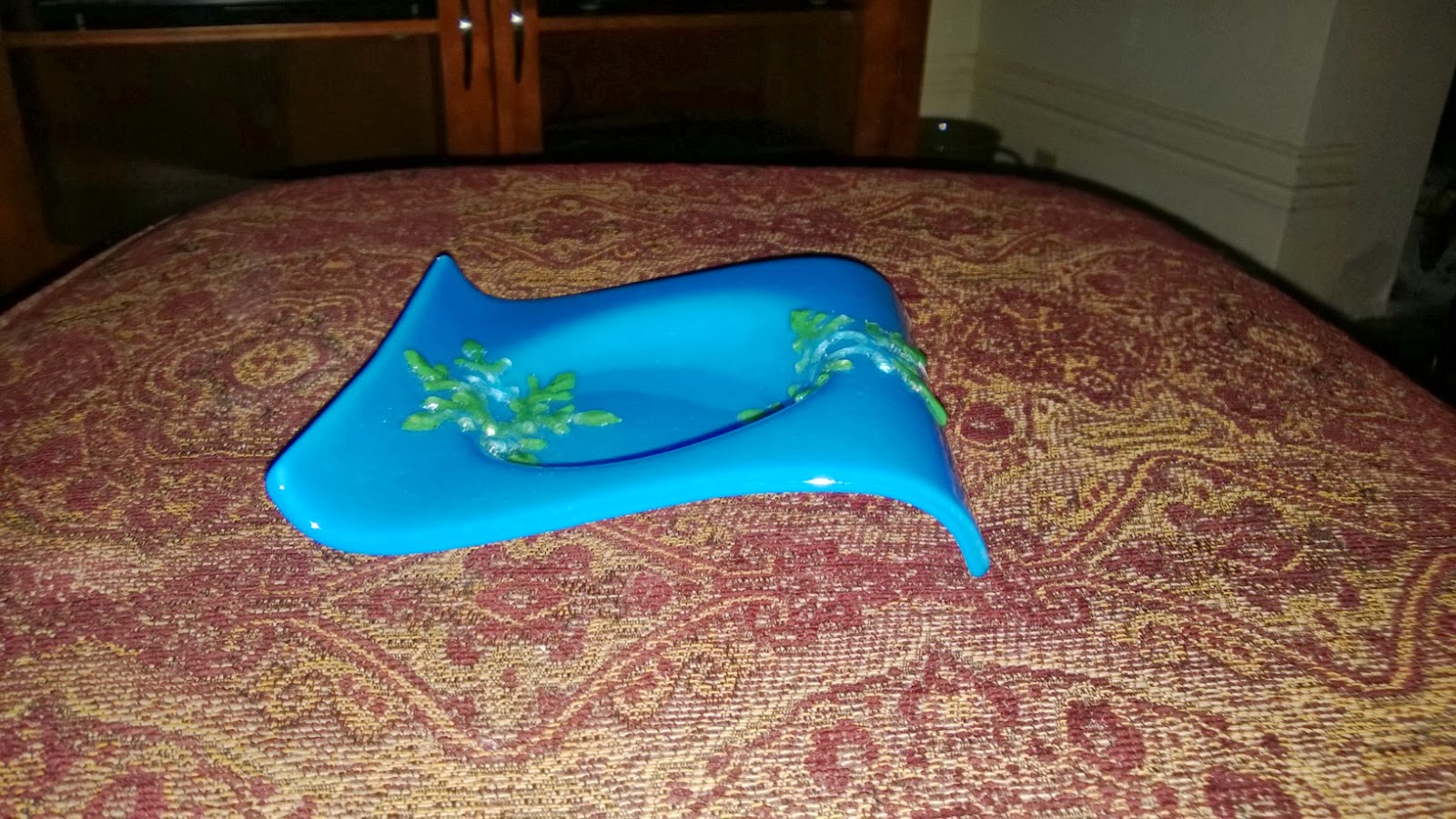

Snowflake wave dish with recess for candle, or candy or keys, whatever

I am doing another wave mold with recess. Already did a white and green one, which was very pretty, and had a few errors but nothing too bad. I forgot to take a picture of it, It is now at my gym, hoping that someone will buy it. And I am doing another, this one has a 3mm blue base, very pretty color, topped with a 2mm clear glass that was cut 1/8th of an inch bigger than the base, with the aim that the top would overlap and include the bottom, making a more finished piece. I ground the pointy corners first. After it comes out of the kiln, I will tack fuse some snowflakes on it and then slump it into the mold. For the panel, I used the following firing schedule:

300dph.............................................1250degrees.....................................hold 30 min

600dph..............................................1420degrees....................................hold 10 min

Full....................................................900degrees......................................hold 1 hour

100dph...............................................300 degrees.....................................OFF

I am fusing only 5mm piece so the corners should somewhat round even though the temperature is not that high. This time I will remember a picture.

Well that came out well, except that it pulled all the kiln wash off of the shelf and I had to soad it in vinegar and water and then scrub it to remove the residue. I placed a sheet of thin fire paper down and put the panel on which I placed to snowflakes. I also added two small projects that I did, wishing to tack fuse those with the following schedule.

300dph.......................................1225 degrees...............................hold 30 min

400dph.......................................1350 degrees...............................hold 10 min

Full...............................................900 degrees...............................hold 1 hour

100dph.........................................600 degrees...............................OFF

This is a higher temperature than the last tack fusing of snowflakes. I wanted less definition.

The above piece was slumped at the following temperature and I think that this schedule is the BEST for this mold:

300dph.......................1220degrees................................hold 40 min

FULL............................900degrees................................hold 1 hour

100dph..........................600degrees...............................OFF

300dph.............................................1250degrees.....................................hold 30 min

600dph..............................................1420degrees....................................hold 10 min

Full....................................................900degrees......................................hold 1 hour

100dph...............................................300 degrees.....................................OFF

I am fusing only 5mm piece so the corners should somewhat round even though the temperature is not that high. This time I will remember a picture.

Well that came out well, except that it pulled all the kiln wash off of the shelf and I had to soad it in vinegar and water and then scrub it to remove the residue. I placed a sheet of thin fire paper down and put the panel on which I placed to snowflakes. I also added two small projects that I did, wishing to tack fuse those with the following schedule.

300dph.......................................1225 degrees...............................hold 30 min

400dph.......................................1350 degrees...............................hold 10 min

Full...............................................900 degrees...............................hold 1 hour

100dph.........................................600 degrees...............................OFF

This is a higher temperature than the last tack fusing of snowflakes. I wanted less definition.

The above piece was slumped at the following temperature and I think that this schedule is the BEST for this mold:

300dph.......................1220degrees................................hold 40 min

FULL............................900degrees................................hold 1 hour

100dph..........................600degrees...............................OFF

Subscribe to:

Posts (Atom)